Buy Sales raffias compacting regrinding and pelletizing system Price

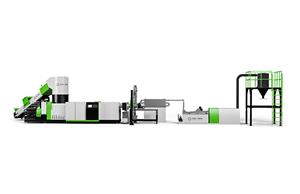

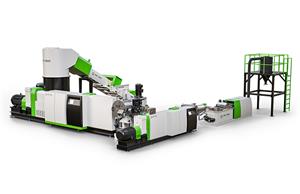

raffias compacting regrinding and pelletizing system

The navigator controls the entire process, allowing the extruder speed and/or melt pump speed to be directly linked to the tool speed, ensuring that the particle size and shape are the same. The relationship between the trend extruder pressure and the extruder speed and the drive load, as well as the alarms and alarms, allow the operator to see the behavior of the raw material and feed system. Water temperature alerts can indicate changes in the process or external changes that are harmful to particle quality.

The researchers developed an improved version of the desktop extruder that could produce filaments for 3D printers, and they also provided assembly instructions online for free.

A student at Michigan Tech university in Horton, Michigan. They developed a device called a recyclable robot, a small plastic recycling system.

"We've developed a new version of the recyclable robot that has enough control to produce commercial-grade filaments with more or less material - we've used balls, regrinds, Even scrap composites like wood prove it. "These plans are completely open source, and most of the components of the new machine design are 3D printed on their own. "

Pierce said in an interview that he saw opportunities for plastic recyclers in several areas. First, the device is a low-cost method for testing composites and polymer mixtures. Recyclers can also use it to produce 3D printer filaments, which are a relatively small market, but the price increases are still huge. Finally, with the widespread use of recycling robot extruders, recyclers will have a new market for selling flakes.

Sales raffias compacting and pelletizing system

"It's still a small market . . . But it is growing significantly. ""It's probably something that some of them are interested in, and our equipment can help them get to market right away. "

Esperol's hardware has released a complete plan and assembly instructions. This article explains how to build a model called RepRapable clebot, which is so named because it caters to a community of 3D printers focused on starting a copy-based rapid prototype.

According to online reports, a recyclable robot can be made of less than $700 in material and completed in about 24 hours. The recyclable robot produces 1 pound of filaments for a 3D printer in 10 minutes per hour. For every pound produced, it consumes 0.11 kWh of electricity.

The researchers estimate that the cost of producing filaments from commercial micropills is about one-fifth that of commercial filaments. It recycles waste plastic into filaments at a cost of about 1.1 cents per pound, while commercial filaments cost more than $11 per pound.

The system can process polymers with extrusion temperatures below 250 degrees Celsius. According to the paper, the company "is able to manufacture custom filaments on a wide range of thermoplastic polymers and composites for material sin and recyclability studies of new materials, as well as new application studies based on 3d printing molten filaments." "

The 2400 series of powder and particle receivers provides a high-capacity sequencing system for handling powder, particle, re-grinding and particle materials. Each receiver has a stainless steel check valve that allows multiple receivers to draw material from a common delivery pipe. Applications include rail truck unloading, silo-to-sky transfer, intra-factory transfer or feeder replenishment.

Buy regrinding and pelletizing system Price

ActiFlow smart solid activators provide an innovative way to reliably prevent the bridging of bonding materials when the stainless steel hopper is stirred without a hopper. ActiFlow is a non-product contact unit consisting of a patent-pending vibration drive and intelligent control unit specifically designed to match the Weight Loss Feeder of the Coperion K-Tron. ActiFlow works with the gravity feeder controller to continuously activate the material in the hopper at optimized frequencies and amplitudes without applying any mechanical force to the bulk material.

Coperion K-Tron's bag dumping station is equipped with an integrated vacuum cover (pictured) designed to maintain a clean, dust-controlled process environment, and is equipped with a pulse cleaning cartridge filter. When the bonnet is opened, the central exhaust automatically activates, creating a slight vacuum. The main filter is only cleaned when the bonnet is closed and the exhaust fan is on. The removal station can handle powdered, granular and granular materials.

But the developers of the RepRapable recycling robot say parts can be found in hardware stores or purchased online. In addition, many parts can be 3D printed, so the filamentfrom the device can be used to make another one.